GEA 10kg/h ATEX spray drier (atomization drying plant)

GEA 10kg/h ATEX spray drier (atomization drying plant)

€250,000 (EUR)

Location:Europe

Description

COMPLETE GEA SPRAY DRYING PLANT

Evaporation capacity: 10 kg/h – Chamber temperature up to 200°C

Previously used for the atomization of water-based solutions, but ATEX certified (except for the premixer).

The system was designed for the atomization of aqueous and solvent-based solutions (ethanol, methanol, acetone, isopropyl alcohol), but was only used for drying an aqueous solution of a plant extract (not classified as hazardous, toxic, or harmful).

The drying chamber is in excellent condition, free from damage or scratches.

---

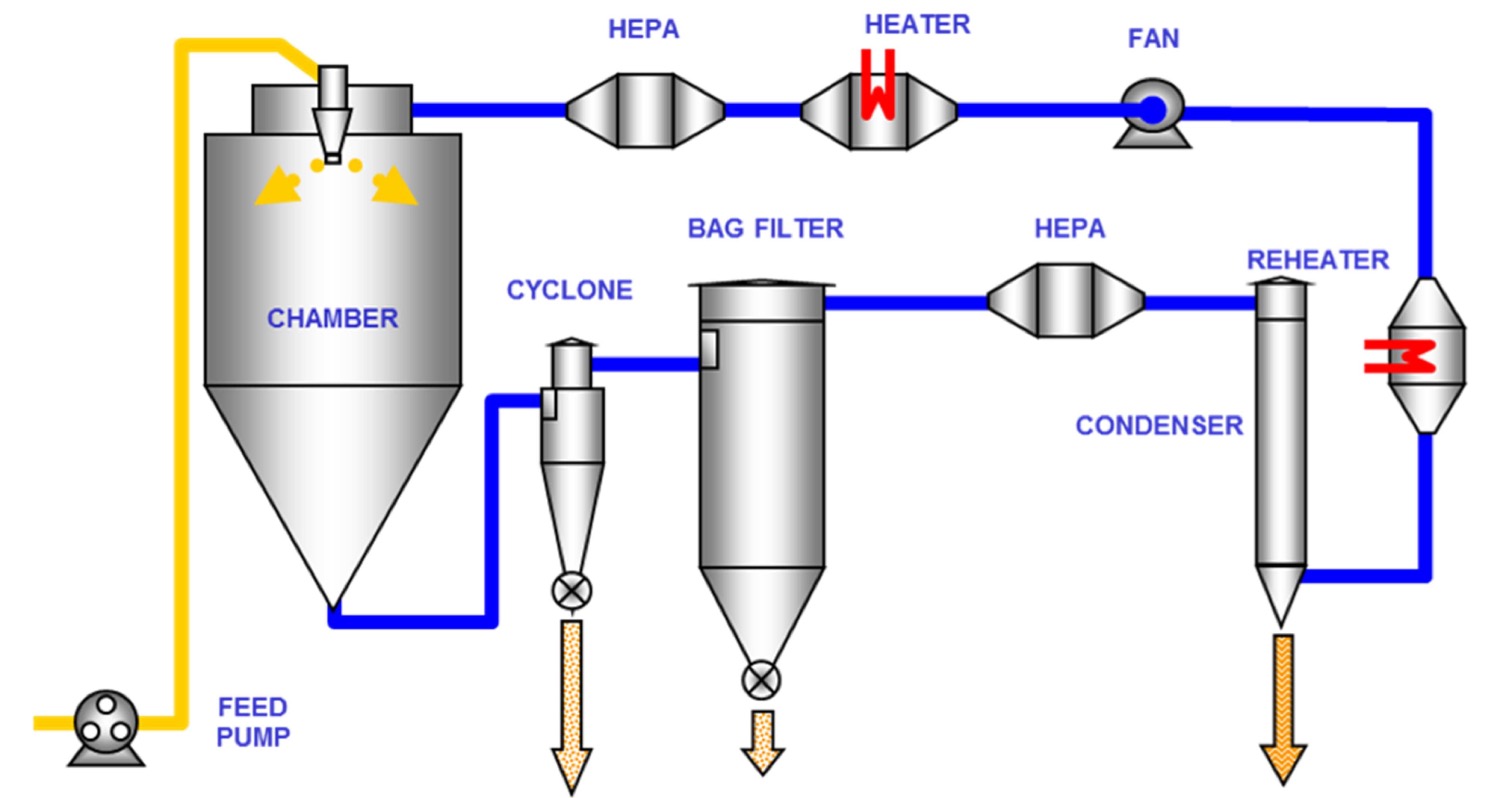

Plant Composition

* Atomization chamber Ø 1.2 m

* Cyclone

* Bag filter with filter socks

* HEPA filters on nitrogen inlet to the drying chamber and downstream of the bag filter

* Condenser for recovery of water/solvent from process nitrogen or air

* Pre-heater

* Nitrogen/air blower

* Reheater

* Peristaltic feed pump

* Agitated and thermostated feed tank (non-ATEX)

* Instrumentation for process control and safety

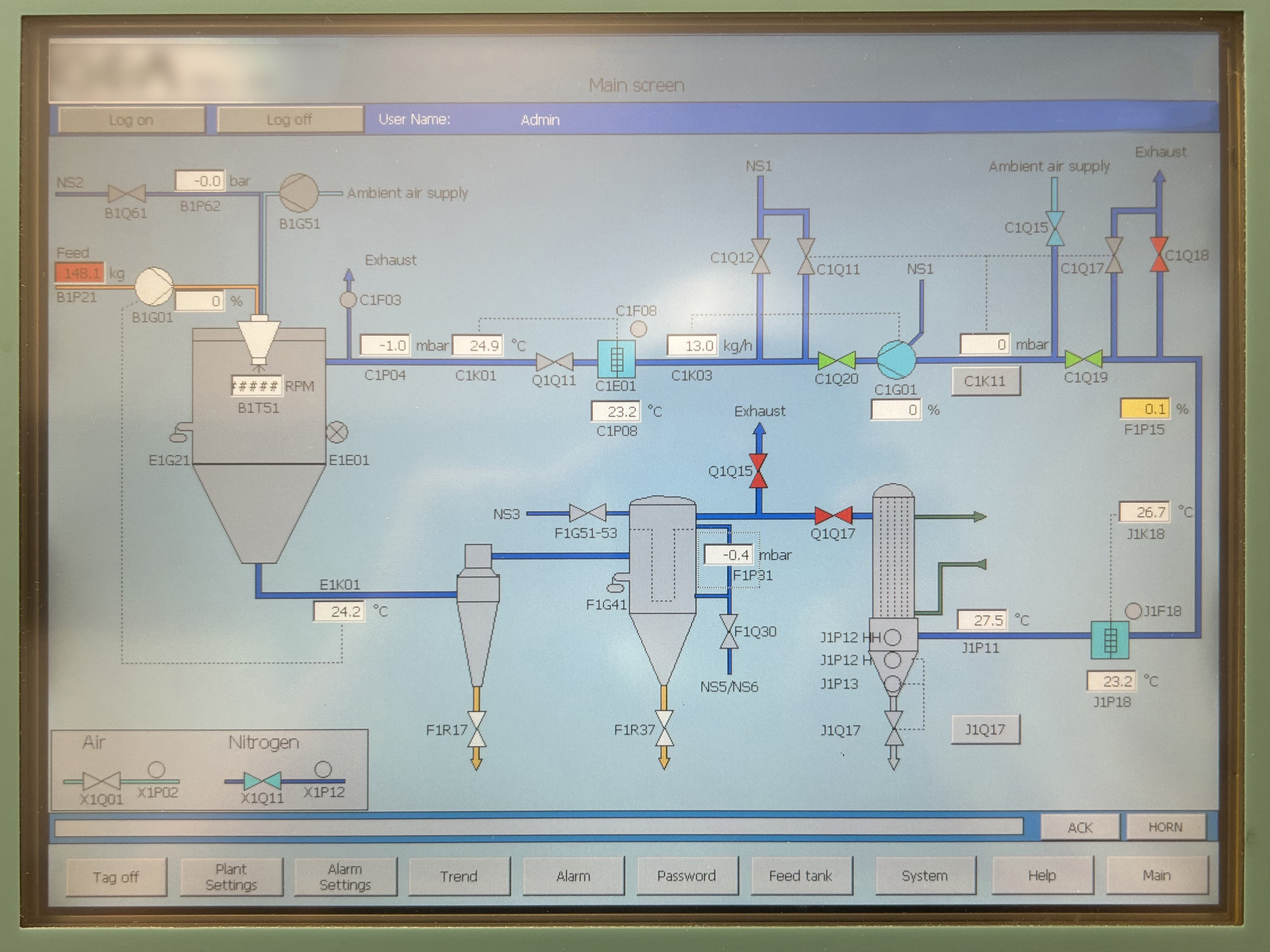

* PLC control system

* Complete documentation

---

Supplied Accessories / Additional Components

* Two atomizers (with spare gasket kits)

* One two-fluid nozzle (software pre-configured for both drying systems)

* Feed tank for peristaltic pump (with operating logic integrated into the software)

* Spare motor for cooling fan

* Two peristaltic pumps (with two additional heads)

* 4” pneumatic butterfly valves (“smart” type), not spare, with spare gaskets

* Needle valves DN40 (with gasket kit) and DN80

* Three sets of Teflon filter socks for bag filter

* Spare instrumentation (pressure transducers, level sensors, oxygen probe transmitter, etc.) — almost complete

* Three rupture discs

* Solenoid valves and coils

* Spare fan belts

* Various fittings and small parts

Optional

Water/glycol chiller unit – Cooling capacity: at -5°C → 32 kW / at -15°C → 22 kW

Price: €25,000**

---

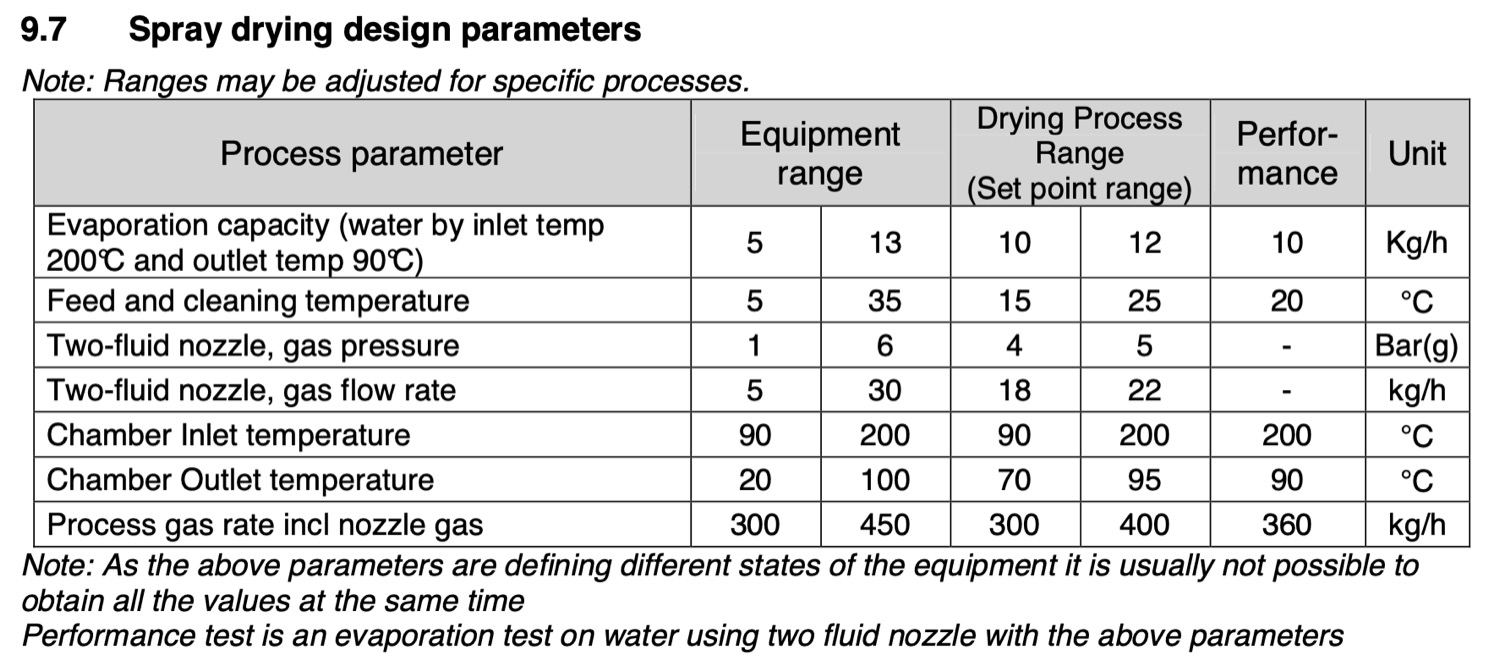

Spray Drying – Process Description (Closed-Cycle Operation)

Spray drying is a method for drying a liquid containing dissolved or suspended solids to obtain a powder product.

Compared to other drying techniques, **spray drying allows very precise control of particle formation**, enabling the production of powders with desired properties such as:

* Density

* Solubility

* Particle size

* Particle size distribution

* Particle morphology

* Taste masking

* Residual solvent content

Note: The plant is supplied "as is", disassembled, without performance guarantees.

Specifications

| Manufacturer | GEA |

| Year | 2011 |

| Condition | Used |

| Stock Number | DR001-LL |